Contract Manufacturing

Contract Manufacturing

Custom Recipe Development

Our R&D team has developed different types of formulas based on their years of experience in solving various skin and health care problems.

Find suitable ready-made formulas or utilize our OEM services to design new skin care products.

Our team helps produce the required fragrance to meet your market preferences.

Emulsification in a sterile workshop

Emulsifies the blended ingredients and ensures the mixture becomes more stable. Our vacuum emulsifier can mix emulsions for more uniform results.

Continuous equipment inspections and maintaining a hygienic environment ensure that the contents of the process are produced under strict standards to meet quality requirements.

Fill Content Efficiently

- It is needed in products to fill with precise content and avoid contamination of emulsified lotions.

- We have machines used to fill lotion products or produce solid cosmetics like lipstick, complete with custom formulas and molds.

- With adjustable filling machines and semi-automatic irregular container filling machines, we achieve high quality and precision at this stage.

Assembly and Packaging

- Final manual assembly and packaging helps make your cosmetic products complete and outstanding.

- Our production capacity of 12 production lines enables us to produce cosmetics in large quantities quickly, thanks to powerful machines and skilled workers. Take advantage of rapid production to meet your deadlines.

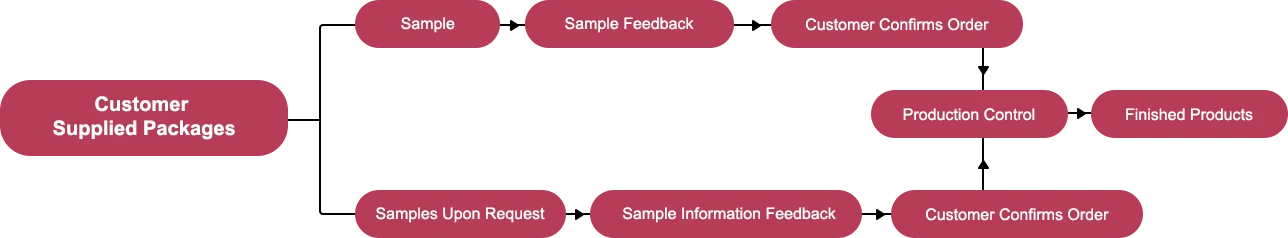

OEM Business Processes

Customize Your Exclusive Products and Get Your Brand Noticed!

You’ll have the collective wisdom of a big team of fashion professionals from around the globe, working hard to ensure that you receive the best quality of product and service available in the industry.